The global demand for lead acid battery recycling machines is surging as industries and governments prioritize sustainability. With over 90% of lead acid batteries being recyclable, this sector offers entrepreneurs a lucrative opportunity to profit while reducing environmental harm. If you’re looking to start a battery recycling business, leveraging lead acid battery recycling equipment to build a scalable, eco-conscious venture.

Why Invest in Lead Acid Battery Recycling Business?

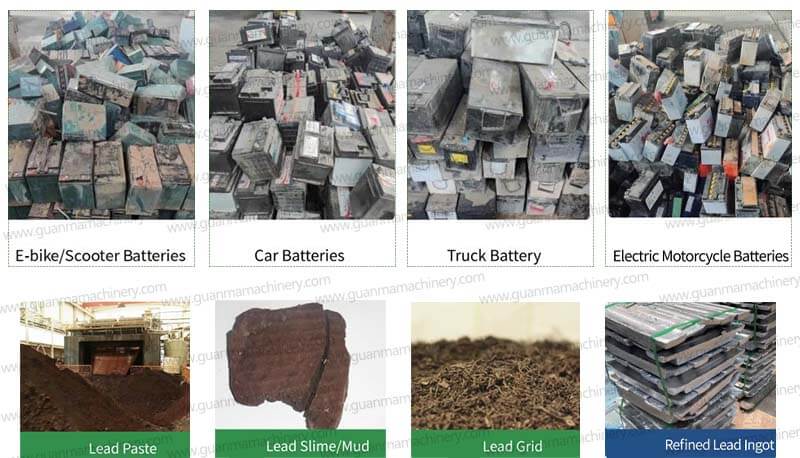

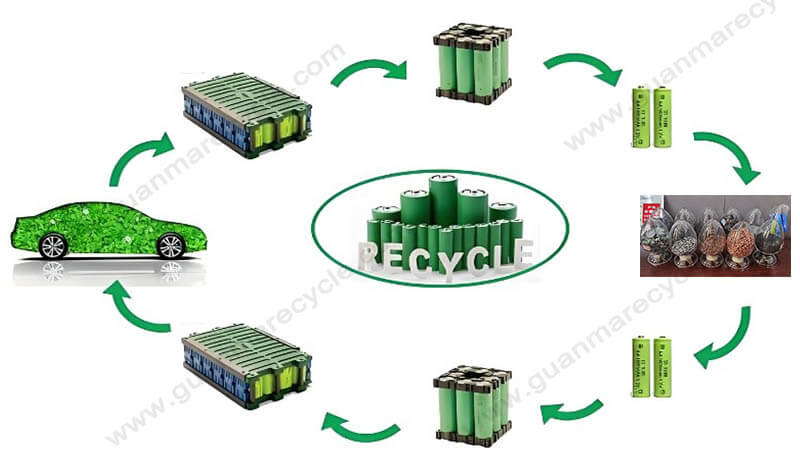

Lead acid batteries power vehicles, telecom systems, and renewable energy storage. However, improper disposal releases toxic lead and sulfuric acid, contaminating soil and water. Recycling these batteries recovers valuable materials like lead, plastic, and electrolytes, which can be reused in new batteries or other industries.

By investing in advanced lead acid battery recycling machines, you tap into a $23 billion market driven by strict environmental regulations and the circular economy trend. Businesses and governments actively seek certified recyclers, ensuring steady demand for your services.

Step-by-Step Guide to Launching Your Business

1. Conduct Market Research and Feasibility Analysis

Identify local and regional demand by analyzing:

Battery waste volume: Partner with auto repair shops, scrap dealers, or telecom companies.

Competitors: Assess existing recyclers and gaps in service quality or pricing.

2. Create a Business Plan

Outline your operational and financial strategy:

Equipment Costs: High-capacity lead acid battery recycling machines range from $50,000 to $500,000, depending on automation and processing capacity.

Revenue Streams: Profit from selling recovered lead (70% of battery weight), plastic casings, and electrolyte neutralization services.

3. Choose the Right Recycling Equipment

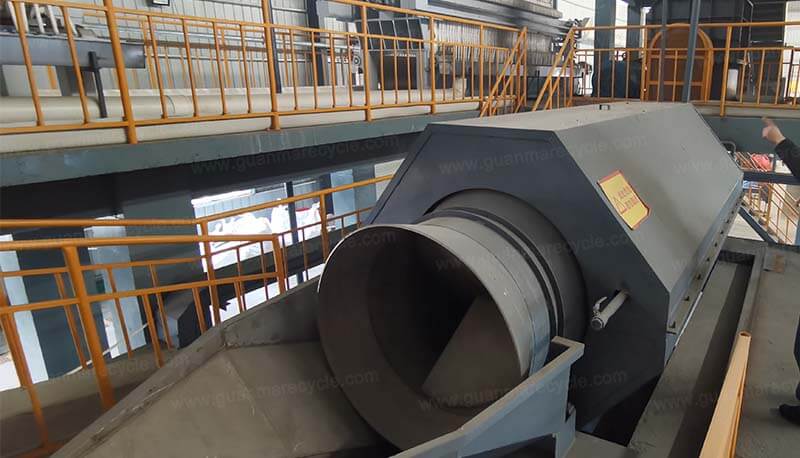

Modern battery recycling machines automate critical steps:

Crushing and Separation: Machines shred batteries, segregating lead, plastic, and acid.

Neutralization: Convert sulfuric acid into sodium sulfate (used in detergents or glass production).

Smelting: Refine lead into reusable ingots.

4. Secure Licenses and Permits

Compliance is non-negotiable. Key requirements include:

EPA/OSHA Approvals: For hazardous waste handling.

Zoning Permits: Ensure your facility meets local environmental and safety codes.

Transportation Licenses: Required for collecting and transporting used batteries.

5. Build a Reliable Supply Chain

Partner with:

Battery Retailers/Manufacturers: Offer pickup services for used batteries.

Scrap Collectors: Negotiate bulk purchase agreements.

Industrial Clients: Target automotive, solar, and UPS battery users.

6. Monitor Finances and Scale

Track ROI using metrics like cost-per-ton processed and lead resale prices. Reinvest profits into:

Expanding Capacity: Add machines to process lithium-ion batteries.

Geographic Reach: Open collection centers in high-demand regions.

Starting a lead acid battery recycling business with specialized machines positions you at the forefront of the green economy.