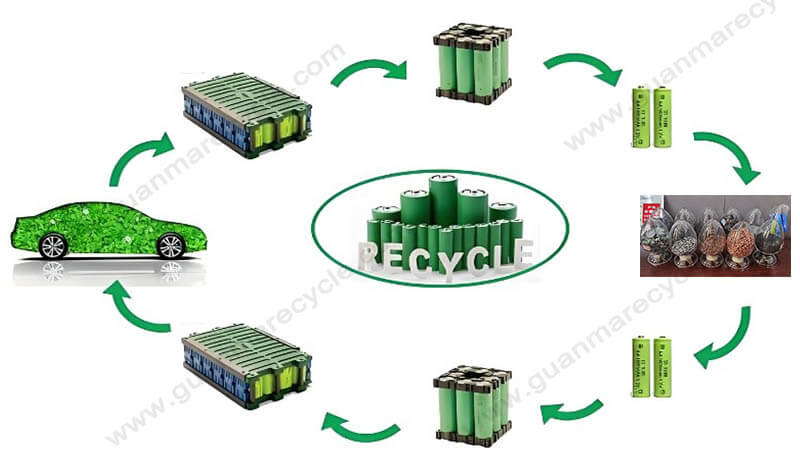

Are you searching for a reliable lead acid battery recycling machine to streamline your waste management process? With the global surge in environmental regulations and the growing demand for sustainable practices, choosing the right recycling equipment is critical for businesses aiming to reduce costs, comply with standards, and contribute to a circular economy.

Key Factors to Evaluate a Lead Acid Battery Recycling Machine

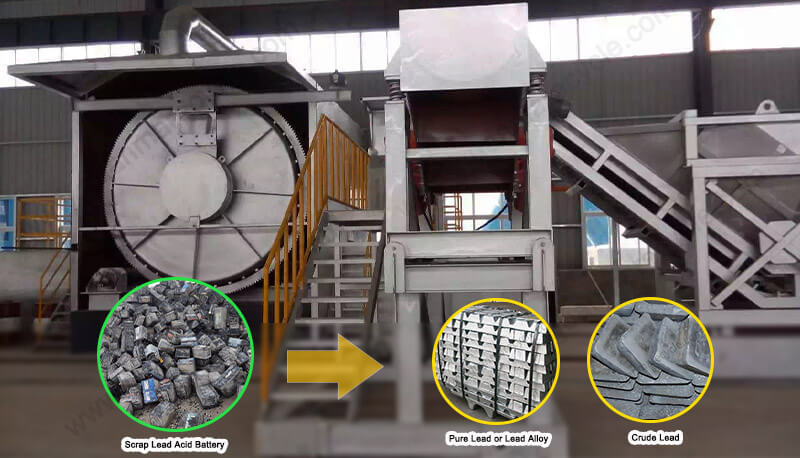

1. Technical Efficiency and Capacity

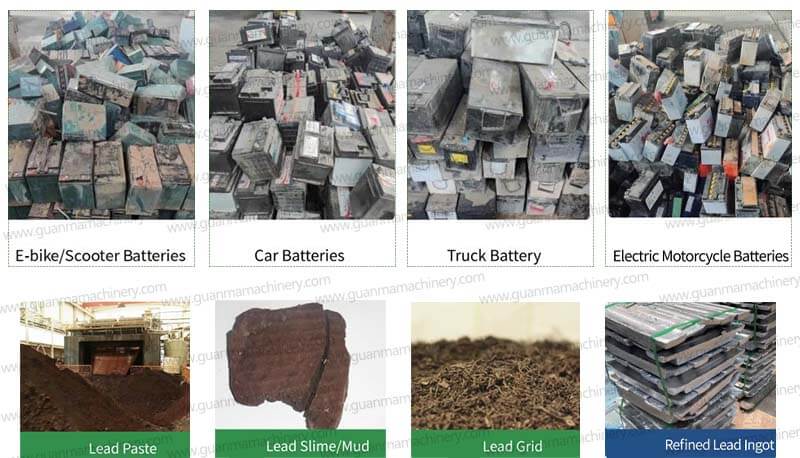

A high-quality lead acid battery recycling line should efficiently dismantle, separate, and recover valuable materials like lead, plastic, and sulfuric acid. Look for machines with advanced crushing, sorting, and smelting technologies that ensure over 95% material recovery rates. For large-scale operations, prioritize systems with a processing capacity of 5–10 tons per hour to meet industrial demands.

2. Compliance with Environmental Standards

Ensure the equipment adheres to international environmental certifications. Machines with closed-loop systems and emissions control mechanisms minimize pollution and avoid regulatory penalties.

3. Durability and Maintenance Requirements

Opt for machines built with corrosion-resistant materials (e.g., stainless steel) to withstand harsh chemical exposure. Modular designs simplify maintenance, reducing downtime and long-term operational costs.

4. Supplier Reputation and After-Sales Support

Partner with manufacturers offering comprehensive warranties, spare parts availability, and 24/7 technical support. Verified suppliers with a global presence.

Why Invest in a Lead Acid Battery Recycling Plant?

Cost Savings: Reclaiming lead and plastic reduces raw material procurement costs by up to 40%.

Environmental Impact: Proper recycling prevents toxic lead leakage and reduces landfill waste, aligning with ESG (Environmental, Social, Governance) goals.

Market Opportunities: With the global battery recycling market projected to reach $24.57 billion by 2030, early adopters gain a competitive edge.

Why Choose Guanma as Your Lead Acid Battery Recycling Machine Supplier?

1. Durable, Low-Maintenance Build

Built with hardened steel components and automated lubrication systems, Guanma’s equipment withstands heavy-duty operations while minimizing downtime.

2. Customized Demos

Guanma Machinery suppliers typically offer on-site or virtual demonstrations to showcase machine performance. Test the equipment’s noise levels, energy consumption, and safety features before purchasing.

3. Tailored Solutions for Unique Needs

Configure solutions based on customer needs such as raw materials and production capacity.

Top FAQs About Lead Acid Battery Recycling Machines

1. What is the average cost of a lead acid battery recycling machine?

Prices range from $100,000 for small-scale units to over $800,000 for fully automated systems. Financing options or leasing agreements can ease upfront costs.

2. How do I maintain the machine for optimal performance?

Regular cleaning, lubrication, and replacing worn components (e.g., blades, filters) are essential. Partner with suppliers offering maintenance training programs.

Selecting the right lead acid battery recycling plant requires balancing technical performance, compliance, and supplier reliability.