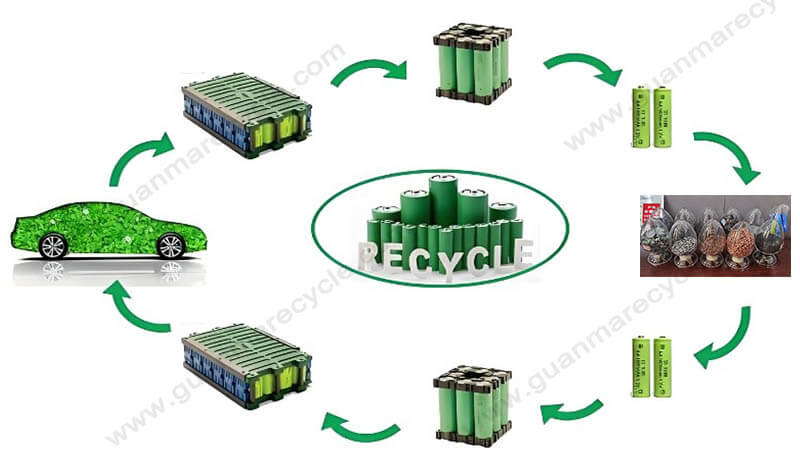

As the world accelerates its transition to renewable energy and electric vehicles (EVs), the demand for safe, efficient lithium battery recycling has never been higher. At the heart of this process lies a critical step: lithium battery discharging. Guanma Machinery lithium battery discharge machine supplier, delivers cutting-edge solutions that ensure safety, maximize resource recovery, and comply with global environmental standards.

Why Lithium Battery Discharging Matters

Before recycling, lithium batteries must be fully discharged to eliminate risks of fires, explosions, or toxic chemical leaks. Traditional methods like saltwater discharge are slow, inefficient, and environmentally harmful. Guanma Machinery’s lithium battery discharge machines offer a revolutionary alternative:

Zero-Risk Safety: Automated systems neutralize residual voltage (0V discharge) with precision.

High Throughput: Process 500–2,000+ batteries per hour, tailored to industrial-scale needs.

Energy Recovery: Capture and reuse up to 90% of stored energy, slashing electricity costs.

For recyclers, OEMs, and battery manufacturers, investing in advanced discharge technology isn’t just a safety measure—it’s a competitive advantage.

Guanma Machinery’s Lithium Battery Discharge Machines: Key Features

Battery recycling equipment supplier, Guanma combines innovation with reliability. Here’s what sets their discharge systems apart:

1. Multi-Stage Discharge Technology

Process: Combines constant-current and pulsed discharge to safely deplete battery energy.

Compatibility: Works with Li-ion, LiFePO4, NMC, and LTO batteries of all shapes (cylindrical, prismatic, pouch).

2. Smart Monitoring & AI Integration

Real-time voltage, temperature, and resistance tracking to prevent thermal runaway.

Predictive maintenance alerts reduce downtime by 30%.

3. Modular Design

Scale capacity seamlessly from pilot plants (100 kg/day) to industrial facilities (10+ tons/day).

Plug-and-play integration with crushing and sorting systems.

Applications Across Industries

Guanma’s discharge machines are engineered for diverse sectors:

EV Battery Recycling: Safely handle end-of-life EV packs.

Consumer Electronics: Process laptops, smartphones, and power tools.

Energy Storage Systems (ESS): Decommission utility-scale lithium batteries.

5 Reasons to Choose Guanma Machinery as Your Supplier

1. Proven Expertise

Guanma has installed 200+ systems across 30 countries.

2. Customized Solutions

Tailor discharge parameters (voltage, current, cycle time) to your specific battery chemistry and throughput.

3. Cost Savings

Recover 85–90% of battery energy to power your facility, reducing operational expenses by up to 40%.

4. After-Sales Support

Global technical teams provide 24/7 remote diagnostics, spare parts, and operator training.

5. Sustainability Leadership

Guanma’s R&D focuses on minimizing carbon footprint—machines use 25% less energy than competitors.

How to Partner with Guanma Machinery

1. Assess Your Needs

Determine battery types, daily volume, and automation requirements.

2. Request a Quote

Visit Guanma’s website for a tailored proposal, including ROI calculations.

3. Onsite Installation

Guanma’s engineers handle setup, testing, and staff training.