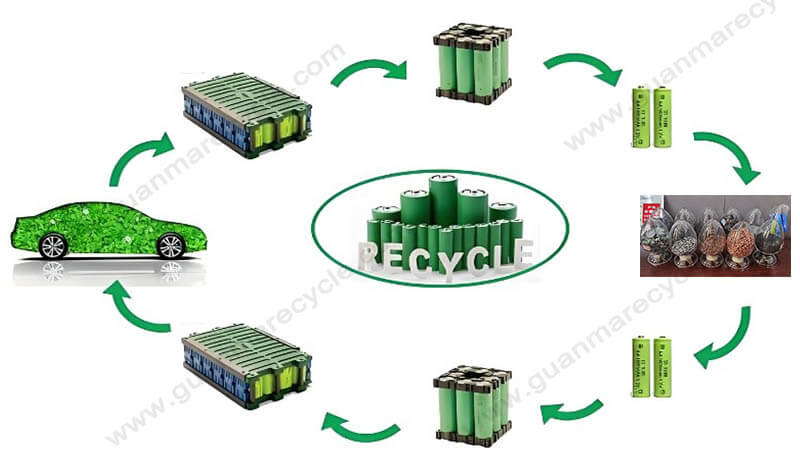

The global shift toward sustainability is accelerating, and by 2025, lithium ion battery recycling plants are poised to become central players in the circular economy. As nations and industries race to meet net-zero targets, the demand for efficient, eco-friendly battery disposal and reuse solutions has skyrocketed.

The Rising Tide of Lithium Ion Battery Waste

Lithium ion batteries power everything from smartphones to electric vehicles (EVs). However, their lifespan is finite. By 2025, over 11 million tons of spent lithium ion batteries will flood global waste streams annually. Without proper recycling, this waste poses environmental hazards, including toxic chemical leaks and resource depletion.

This crisis creates an urgent need for scalable lithium ion battery recycling solutions—a gap that specialized recycling plants are uniquely positioned to fill.

3 Reasons Lithium Ion Battery Recycling Plants Will Lead the Circular Economy

1. Surging Demand for Sustainable Raw Materials

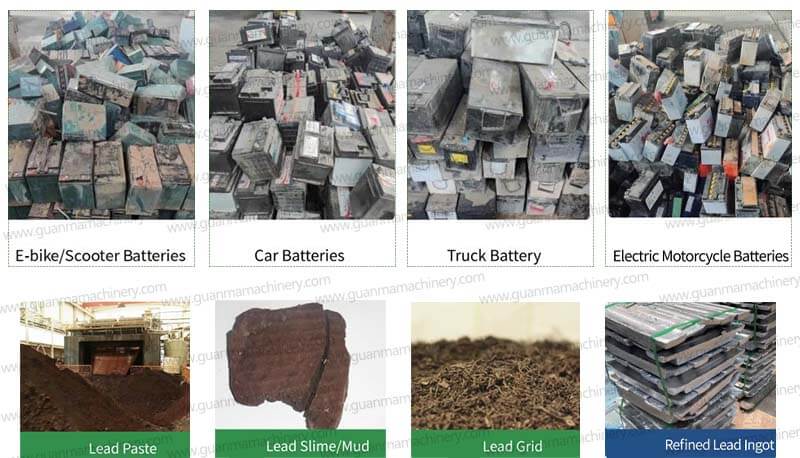

Lithium, cobalt, and nickel—key components of batteries—are finite resources. Mining these materials is environmentally destructive and geopolitically fraught. Recycling plants recover up to 95% of these metals from used batteries, reducing reliance on mining and stabilizing supply chains.

By 2025, recycled materials are projected to meet 30% of global battery production needs. Companies investing in EV battery recycling technologies today will secure cost-efficient, sustainable raw materials tomorrow.

2. Government Regulations Driving Compliance

Global governments are enforcing strict regulations to combat battery waste. The EU’s Battery Regulation 2023 mandates that 70% of lithium from spent batteries must be recycled by 2030. Similarly, the U.S. Inflation Reduction Act offers tax incentives for domestic battery recycling initiatives.

Non-compliance risks hefty fines, making partnerships with certified lithium ion battery recycling facilities a strategic necessity for manufacturers.

3. Profitability Meets Sustainability

Recycling isn’t just eco-friendly—it’s lucrative. Recovered materials like lithium carbonate sell at 80% of virgin material costs, offering manufacturers significant savings. Additionally, the global battery recycling market will exceed $23 billion by 2025, attracting investors and innovators.

Forward-thinking businesses are already capitalizing on this dual benefit, integrating closed-loop battery recycling systems into their operations.

How Recycling Plants Are Revolutionizing the Industry

Modern lithium ion battery recycling plants use cutting-edge technologies to maximize efficiency:

Hydrometallurgical Processes: Extract metals using eco-friendly chemical solutions.

Direct Recycling: Refurbish cathode materials without full breakdown.

AI-Powered Sorting: Enhance recovery rates and reduce operational costs.

These advancements position recycling plants as indispensable partners in achieving a zero-waste future.

Preparing for 2025: A Guide for Businesses

To stay competitive, companies must:

1. Partner with Certified Recyclers: Ensure compliance and access high-quality recycled materials.

2. Adopt ESG Frameworks: Align with sustainability goals to attract investors and customers.

3. Invest in R&D: Innovate recycling methods to handle next-gen solid-state and EV batteries.

The Future Is Circular

By 2025, lithium ion battery recycling plants will dominate the circular economy, driven by regulatory pressures, resource scarcity, and technological breakthroughs. Businesses that embrace sustainable battery disposal methods and recycling infrastructure today will lead tomorrow’s green economy.